Many industrial and construction sites have the potential to expose their staff to harmful dust or vapours and gases. Inhalation is usually the most significant route of entry into the body and so monitoring the air they breathe is vitally important.

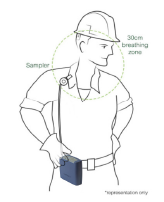

In general terms we draw a known volume of air using a sampling pump through a suitable sampling medium. For particulates and fumes it would be a filter paper or suitable solid media and for gases and vapours through a sorbent tube or sometimes an impinger/bubbler. A typical sampling train for personal monitoring would look like this with the sampler mounted in the breathing zone;

For grab samples of gases, a gas sampling bag is used, e.g. a Tedlar bag. It is also possible to measure background exposure via Diffusive or Passive sampling. These are sealed badges which are opened for sampling, worn on the person for the recommended time, sealed and sent off for analysis.

Please consult your standard method or the Hazard Search to find out what equipment you need.

Sampling for Dusts and Fumes

Dust is particles of solid material around 1µm to 1mm diameter. Larger particles are too heavy to remain airborne. Fumes are smaller than dust. They are solid particles formed by condensation from a gas and the particle size is typically <1µm.

There are different exposure limits for Total Inhalable dust and Respirable Dust. Total Inhalable Dust is the fraction of particulates (up to 100µm) that enters the nose and mouth during breathing and can be deposited anywhere in the respiratory tract. Respirable dust, however, is smaller (up to 10µm) and can penetrate into the deep lung where gas exchange takes place. Different sample heads are needed to measure the different fractions.

Total Inhalable Dust Head

Sampling media (filters) are placed inside the head and clipped onto clothing in the breathing zone. A controlled rate of air via a personal sampling pump is drawn through the filter which has been pre-weighed. The filter is weighed after sampling to determine the amount of dust collected. All particle sizes will be collected.

Respirable Dust or Cyclone Head

Respirable fraction sampling heads or ‘cyclone’ heads are specifically designed to separate out the smaller dust fractions collecting particle sizes of <10µm onto filters.

Filters and Filter Media

Filters are available in a number of different materials, the most common type is Glass Fibre where gravimetric weighing is the only analysis. If further analysis is required or the hazard being sampled is corrosive or if there is interference with glass fibre then other types are recommended, e.g. Mixed cellulose ester (MCE), PVC, PTFE, Polycarbonate, Quartz, Silver. Please refer to the Filters Selection page for more information. Please also check your standardised method for the correct filter to use. Filters are also available pre-weighed or pre-loaded into cassettes.

Calculations of Exposure

| Concentration (mg/m3) | = | Weight Gain (mg) x 1000 |

| Flow rate (l/min) x time (min) |

Sampling for Solvents and Vapours

Solvents, gases and vapours are sampled actively in a similar way to particulates but instead of filter and head, a sorbent tube is used or sometimes a bubbler/impinger.

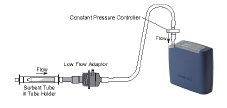

Above is a typical sample train using a sorbent tube. The ends of the sorbent tube are broken off and inserted into a tube holder which is then connected to a personal sampling pump. Generally the flow is lower (typically 20-100ml/min) and so either a dedicated low flow pump may be used or a medium flow pump, i.e. Apex2 with a Constant Pressure Controller and Low Flow Adaptor. Flow rate needs to be set pre and post sampling.

A sorbent tube contains a material which adsorbs the vapour or gas onto its surface during sampling. Charcoal is the most common sorbent material but Silica Gel, Chromopak, Tenax and others are also used dependent on the standard method. Please refer to the Sorbent Tube pages for more information. Also please refer to your standard method to find out which sorbent tube you require or search on the Hazard Pages.

Most tubes have two layers of material where the smaller layer is the ‘back up’ and should be closest to the sampling pump inlet. Samples should be taken with the tube in a near vertical position on the body. The two layers are analysed separately and if the ‘back up’ layer is more than 10% of the main layer, the tube is deemed to be saturated and another sample must be taken varying the parameters (time, flow rate, size of tube etc.)

Bubblers and Impingers

This is a means of sampling replacing the solid sorbent tube with a liquid. Impingers have a tapered outlet which allows particulate matter to exit at high velocity, hit the flask bottom and be captured in solution. Bubblers are open or fritted to increase the surface area so the gases are absorbed into solution. This is a preferred method. Impingers and bubblers can be positioned in an area, held or mounted in a holster.

Here is a typical sample train for an impinger/bubbler:

After sampling the tubes or the sampled liquid are sealed and sent off to a laboratory for further analysis. The sorbent tubes are desorbed either chemically or thermally and for an impinger/bubbler, the sampled liquid is analysed, generally by Gas chromatography.

Calibration

A standard method (e.g. NIOSH, OSHA, MDHS) will recommend a flow rate for sampling. This needs to be set using a calibrator pre-sampling and post sampling. A simple rotameter may be used in the field or a digital flowmeter.